Introduction

Futuristic product design and 3D printing have emerged as a new revolution in today’s world. This technology is not only making product development faster and more effective but through this, we are also able to cross the limits that seemed impossible earlier. In this article, we will learn how both these technologies are shaping future product design and how they are bringing changes in the industries.

Futuristic Product Design: What is its Importance?

Futuristic product design means that we design products according to current and future technological needs. This design not only improves the user experience but also adds innovation and functionality to the manufacturing process of those products. Futuristic design often includes elements that take into account not only utility but also aesthetics and environmental impact.

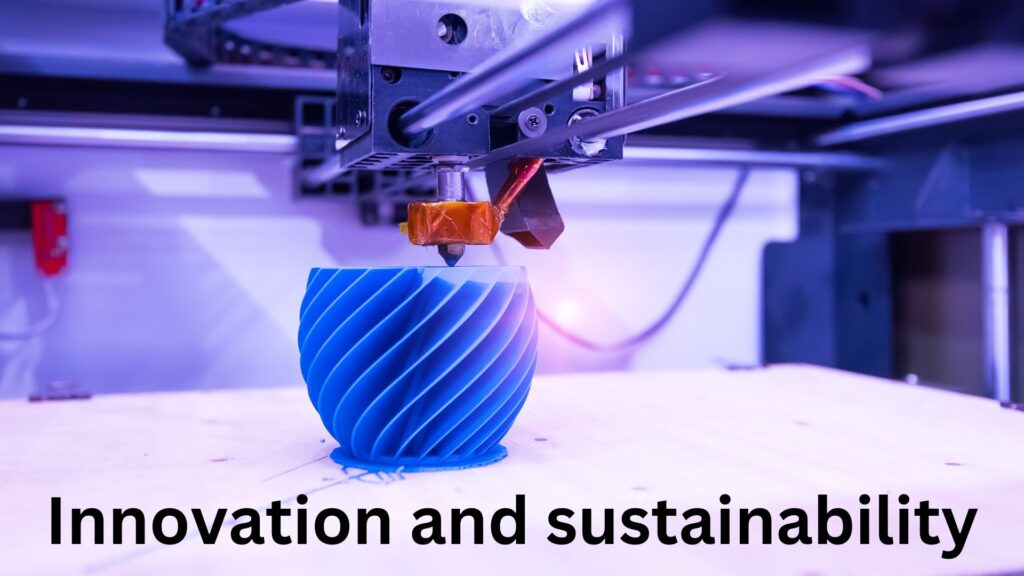

Innovation and sustainability: the core pillars of futuristic design

Image credits: canva.com

Innovation and sustainability are two important elements that form the foundation of futuristic design. Products are designed in such a way that they are not only technologically advanced but also environmentally friendly. For example, products like solar panels and electric vehicles are designed in such a way that they reduce energy consumption and conserve natural resources.

3D printing: A new approach in product manufacturing

3D printing has changed the traditional methods of product manufacturing. It uses a type of enhanced manufacturing process to create a real object from a digital model. Through 3D printing, we can create complex designs in less time and at a lower cost. Its biggest advantage is that it is much more accurate and cost-effective than traditional manufacturing processes.

Different techniques of 3D printing and their uses

FDM (Fused Deposition Modeling): This is the most common and inexpensive 3D printing technique, in which plastic threads are deposited on top of each other by heating. It is used for prototyping and small-scale production of products.

SLA (Stereolithography): In this technique, a liquid resin is converted into a solid form using UV light to create a 3D model. This technique is used for more precise and high-quality products.

SLS (Selective Laser Sintering): It uses powdered material that is melted by a laser and turns into a solid structure. It is used in the manufacture of strong and complex structures.

A blend of futuristic design and 3D printing

When futuristic design and 3D printing meet, it not only speeds up the design process of products but also brings about many significant changes in the industries. With the help of 3D printing, products can be designed in a more personalized and customized way. Moreover, this technology allows us to create complex and unique structures without any additional cost.

Customization and individuality

3D printing has given a new direction to customization and personalized design. Now companies can create products specifically designed for their customers. For example, products such as fitness equipment, smartphone cases, and orthopedic devices can be individually designed, giving the user a more comfortable and convenient experience.

Impact on industries

- Automobile Industry: 3D printing is being used in the automobile industry for spare parts and prototyping. It makes the production process of the industry faster and more precise.

- Healthcare: 3D printing is now being used to create bone implants and custom-made devices that are more personalized and precise for patients.

- Fashion and Jewellery: 3D printing has revolutionized the process of custom jewelry and fashion design. Now designers can turn their imaginations into reality.

The role of 3D printing in futuristic product design

3D printing is playing a vital role in futuristic design. It allows designers to unleash their creativity without any limits. Designers can now convert their imaginations into digital format and then use 3D printers to bring them into reality. Through this, products can be made more convenient, durable, and eco-friendly.

Social and environmental impact

Image credits: canva.com

3D printing and futuristic design are important not just from a technological, but also from a social and environmental perspective. This technology uses fewer resources, making the production process more sustainable. In addition, it also reduces the creation of unnecessary products and waste. As the tools for 3D printing and futuristic design become cheaper and more accessible, we can expect their impact to be even greater on a global scale.

Conclusion

Futuristic product design and 3D printing have completely changed the way we design and manufacture. With the help of these technologies, we are creating more customized, sustainable, and tailored products, which was never possible before. In the future, these technologies will give a new direction to not only industries but also to society, which will contribute towards the conservation of natural resources and sustainable development.

FAQs

1. What is Futuristic Product Design and 3D Printing?

Futuristic product design is the process of creating new and innovative products using advanced technological solutions. 3D printing, also known as additive manufacturing, is a technique in which designed objects are created directly in three dimensions through a computer-controlled printer. Both these techniques make products more customized and sustainable.

2. What are the advantages of 3D printing in product design?

3D printing has many advantages such as the ability for customization, lower production costs, faster prototype creation, and less waste generation compared to traditional manufacturing methods. It allows designs to be tested and improved quickly, leading to more effective and creative solutions for designers.

3. Can 3D printing only be used for small products?

No, 3D printing can also be used for large and complex products. It is being used in the manufacture of large parts in the aircraft and automobile industries. 3D printing technology is also being adopted for large-scale manufacturing, making advanced designs and custom solutions possible.

4. What is the future of 3D printing in futuristic design?

The use of 3D printing will be more widespread in the future, as it can make product design and manufacturing more flexible, custom, and sustainable. Also, it expands possibilities such as the creation of personalized medical devices, custom fittings, and the use of recycled materials. Moreover, it will play an important role in the creation of smart and intelligent designs in the future.

5. Are products made from 3D printing sustainable?

It depends on the material used and the type of design. Generally, high-quality materials such as steel, titanium, and special plastics can be used in 3D printing, which are durable. However, if low-quality materials are used, the durability of the product may be affected.